作为全球众多致力于开发钙钛矿太阳能电池商业潜力的研究小组之一,来自日本冲绳科学技术大学院大学(OIST)能源材料和表面技术部门的研究人员开发出了一种能扩大其商业化生产的新工艺。

钙钛矿的低成本、高效率潜力早已为人们所熟知,而对其的开发研究,飞速推动了这一技术的发展。OIST 的Yabing Qi教授表示,钙钛矿电池的研究领域前途一片光明,仅用了九年的时间,这些电池的效率已经从3.8%提升至23.3%。

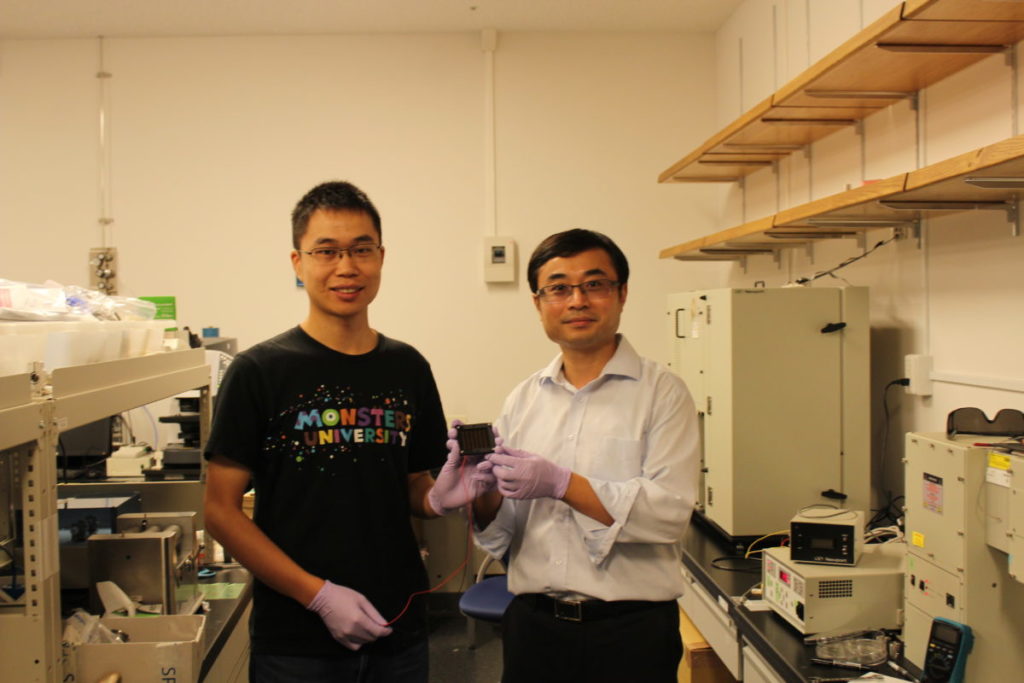

OIST小组的研究成果,已经发表在Nature Communications杂志上,题目为《Gas-solid reaction based over one-micrometer thick stable perovskite films for efficient solar cells and modules》。文中表述,这一设施使用气固相反应基技术制造而成。板材基底首先被涂覆上一层掺入少量氯离子和甲胺气体的三碘化氢铅。研究人员表示,这使他们能够制造出统一、可复制的面板。

这一新成果的关键在于使用了1微米厚的活性钙钛矿层。据称这种较厚的涂层可以提高太阳能电池的稳定性,并简化生产工艺,从而降低成本。研究人员们将这一工艺从一个0.1mm²的原型扩展到一个5x5cm的电池组件。尽管面积的扩大将电池转换效率从19.1%降低到了15.3%,但研究小组表示他们目前正在集中精力进行改进,并相信这一工艺能在未来几年内投入商业使用。

与此同时,英国的钙钛矿专业公司Oxford PV也正在引领着钙钛矿技术的商业化开发。该公司最近宣布就37%高效钙钛矿电池的研究计划,征集合作伙伴。该公司之前还曾表示,已经成功地将其在硅串联电池上的钙钛矿材料放大到“全尺寸”的156x 156mm,而效率仅有“微小差异”。

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.