泰国玛希隆大学的科学家们利用基于反溶剂沉积和真空热退火(VTA)的制造工艺,开发了用于低光照应用的三阳离子钙钛矿太阳能电池。

他们说:“VTA导致紧凑、密集和坚硬的形态,同时抑制表面和晶界的陷阱状态,而这正是激子损失的重要原因,”他们强调了第二步对于产生高质量钙钛矿层的重要性。“由于室内光照强度至少比太阳光低300倍,通过真空热退火诱导形成致密均匀的钙钛矿层是有价值的。”

研究人员通过与压力可控的真空泵相连,并位于一块热板顶部以调节温度的真空烧瓶实现了该过程。他们使用了一种被称为FA0.45MA0.49Cs0.06Pb(I0.62Br0.32Cl0.06)3的钙钛矿材料,用溴和氯处理后,其能带隙为1.80eV。

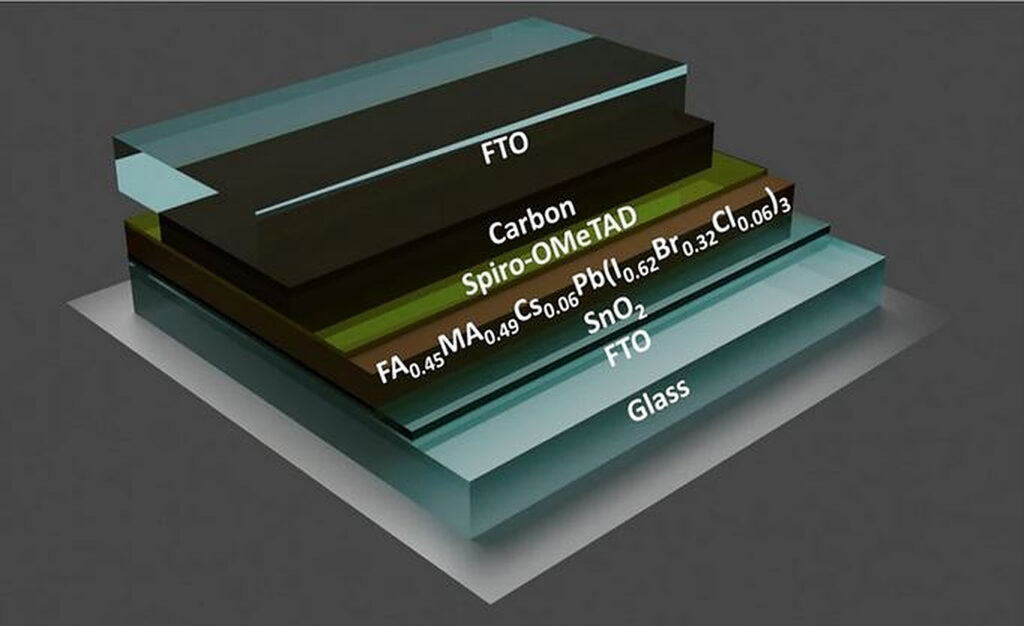

他们用掺氟二氧化锡(FTO)制成的基板、基于锡(IV族)氧化物(SnO2)的电子传输层(ETL)、钙钛矿吸收剂、由Spiro-OMeTAD制成的空穴传输层(HTL)、碳顶电极和另一个FTO层构建起电池,其有效面积为0.04 cm2。

在1000lux的室内光线下测试,该太阳能电池显示出27.7%的能量转换效率、0.93 V的开路电压、0.16 mA/cm2的短路电流,以及32.0%的峰值效率。而未经VTA处理的参考装置的效率为25.5%,开路电压为0.91V,短路电流为0.16mA/cm2,峰值效率为30.7%。

该小组在谈到基于VTA的电池的优越性能时说:“VTA导致表面粗糙度降低,以及在体部和表面的电子陷阱。VTA为稳健的钙钛矿结构形成打开了大门,并可实际地适用于各种钙钛矿电池组成,以实现现代社会理想的光电应用。” 他们在《科学报告》上发表的《通过真空热退火形成稳健钙钛矿层,用于室内钙钛矿太阳能电池》中介绍了该电池。

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.